#13: STC Deep Dive - Micromobility

If you’ve followed The SMART Tire Company over the past year, there’s a good chance you first discovered us via METL™: our world’s first airless, shape memory alloy tire.

If you’re a cyclist, it’s obvious why that excites you, but why did we decide to build a bicycle tire first? What about automotive, or space? Where do scooters fit into this? There’s a lot to cover, so let’s take a deep dive into our exciting go-to-market: micromobility.

NOTE: this is Part 1 of a series of deep dive updates into SMART tire technology. Have a topic you’d like to see covered? Please let us know!

Micromobility: What Is It? How Big Is It?

There a are few definitions floating around, but this one from Wikipedia covers it pretty well:

Micromobility refers to a range of small, lightweight vehicles operating at speeds typically below 25 km/h (15 mph) and driven by users personally (unlike rickshaws). Micromobility devices include bicycles, e-bikes, electric scooters, electric skateboards, shared bicycle fleets, and electric pedal assisted (pedelec) bicycles.

If you live in a city serviced by Bird (IPO 2021), Lime (over $1B raised), Spin (acquired by Ford), Lyft (IPO 2019) or Tier Mobility (new market leader), you are already accustomed to seeing shared electric scooters and dotting the sidewalks. In many places, there are shared e-bikes for rent. Ok, but how big is this industry really, and is it just a fad?

Wow! This is just the shared micromobility market. Personal use vehicles are not yet included. Take e-bikes for example. Currently a $25-$30B industry, they are projected to reach $50B by 2030.

SMART Opportunity: shared electric scooters

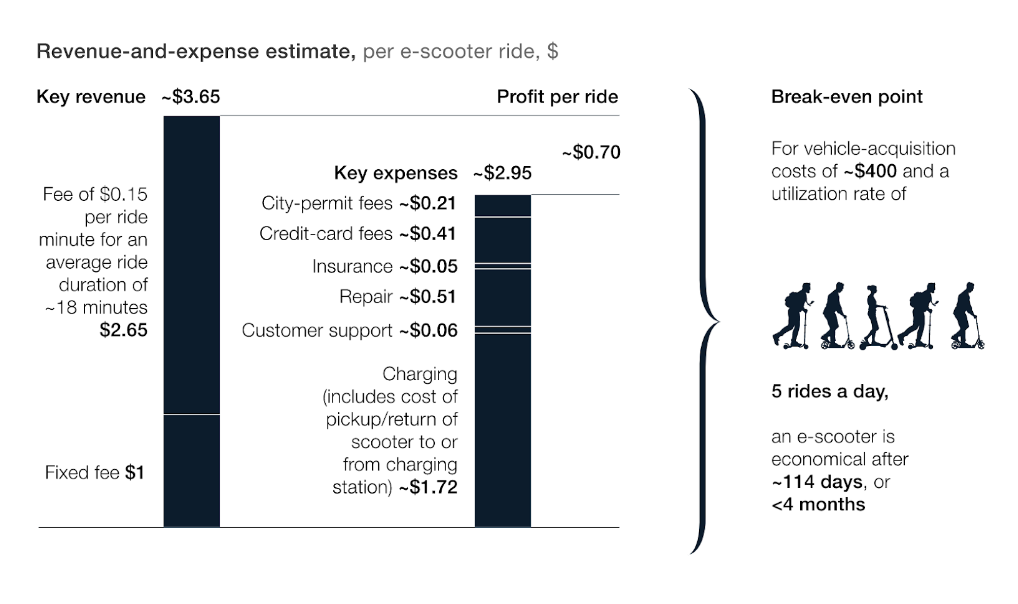

So the micromobility market is pretty big, but what is the opportunity for tire technology? Let’s start with a look at the economics of shared electric scooters. Note: electric scooter provider Spin Mobility is an early R&D partner with STC.

Key takeaways:

14% of all revenue goes to repair costs, and almost 50% to charging

This equates to $76.50/month in repairs and $258.00/month in charging

The vehicle acquisition cost is equal to a mere 35 days of operation

City permits, credit card fees, insurance and customer support are unlikely to get any cheaper, so what can we do? We can improve the single most frequently repaired component on the scooter: the tires.

No flats = repair costs down

Durability = less downtime

Better fuel efficiency = reduced charging costs

Safer ride = competitive advantage for city permits, lower insurance premiums

METL & The Holy Grail of Cycling

There’s a simple reason why our METL tire went viral, and it’s not just because it looks cool and comes from NASA. The reason for excitement is simple: airless tires sound great, but they usually fail to deliver. Who wouldn’t want to get rid of flat tires forever?

The moment you try a solid tire on your bike, you’ll see the issue. Your flats are gone, but the whole experience is bad. There’s a reason why most major tire companies ignore airless applications altogether: the ride is rough, and/or it’s more work to pedal (high rolling resistance).

The material that makes up the structure of a METL tire, called Nitinol, is different from anything used before. Nitinol has:

The highest energy return of any material previously used in a tire (fuel efficient)

Shock absorption & elasticity (smooth ride)

That’s the key: new materials unlock our ability to make tires that are practically indestructible, fuel efficient, and with a smooth ride. The first high performance, airless tire for micromobility.

Proprietary Technology

New innovations are exciting, but competition can be fierce. How do we know STC will be the company to capitalize on nitinol tires?

We have an exclusive license to NASA tubular SMA technology for micromobility (read here). Exclusivity is not easy to obtain from the federal government, and requires us to demonstrate our unique ability to produce viable, commercial products.

We have filed several provisional patents for new innovations necessary to bring METL to market. Without wheel integrations, rubber integrations, encasement and manufacturability, the barriers to entry are extremely high for producing a competing tire, even after navigating around NASA patents.

First mover advantage & scarcity of knowledge: through our internal team and our Space Act Agreement with NASA Glenn Research Center, STC is the only company able to leverage FEA modeling of nitinol, with experience building nitinol tires, and with a 2 year head start (so far).

FAQ and The Future

For frequently asked questions about METL tires, including cost, traction and performance, please visit our WeFunder FAQ.

What’s next for METL?

In 2021, we optimized the cost of our bicycle tire by over 80%. We are now approaching 90% and a point where we’re comfortable going to market.

Tires are being lab and field tested to ensure consistent safety and performance under all conditions

We are perfecting our continuous manufacturing process, to ensure we can keep up with demand, and keep costs down

Based on our experience building the METL bicycle tire, we are entering the final stages of our electric scooter tire design. We hope to complete the first pilot test on a shared vehicle fleet in 2023.

How You Can Help

Our current bridge round of funding here on WeFunder is extremely important to the launch of our micromobility products in 2023.

As a current or future owner of STC shares, you can help us achieve our goals. Please take a moment to:

SHARE the campaign on your social media

SHARE with your friends and family who may be interested. Do you know any avid cyclists?

Reserve the maximum amount possible during the early stage of our campaign. Big numbers = big momentum early in the campaign!

Have more questions about micromobility or METL tires not covered here? Please send us an email at hello@smarttirecompany.com.

MOBILITY.TIRES